About Us KIP is a registered company, incorporated in 2008 to provide quality work, consultation and advisory services in the field of Accounting, Auditing and Assurance, Taxation and regulatory, Company registration, LLP formation, Project reports and Business registrations to its clients. KIP is managed by a very strong team of qualified and experienced professionals comprised of Chartered Accountants, Management Graduates and Post-Graduates.

Very informative article. We introducing this project to our investor group. Please share project details for higher Mega Watt projects and oblige.

Welcome in KIP

Great thanks for showing interest.

Further, you’re requested to kindly share your contact number so that we can contact to you for your requirements.

You may also connect with us on 8683898080.

Thanks & Regards

I am interested, kindly send details.

Welcome in KIP

Great thanks for showing interest.

Further, you’re requested to kindly share your contact number so that we can contact to you for your requirements.

You may also connect with us on 8683898080.

Thanks & Regards

I’m interested in biomass plate manufacturing

Welcome in KIP

Great thanks for showing interest.

Further, you’re requested to kindly share your contact number so that we can contact to you for your requirements.

You may also connect with us on 8683898080.

Thanks & Regards

Very useful data and business development.But more information we require.Cost of production and marketing also profit.Expect you send me on mail.

Welcome in KIP

Great thanks for showing interest.

Further, you’re requested to kindly share your contact number so that we can contact to you for your requirements.

You may also connect with us on 8683898080.

I am interested

Call me 8199078080

Welcome in KIP

Great thanks for showing interest.

Further, you’re requested to kindly share your contact number so that we can contact to you for your requirements.

You may also connect with us on 8683898080.

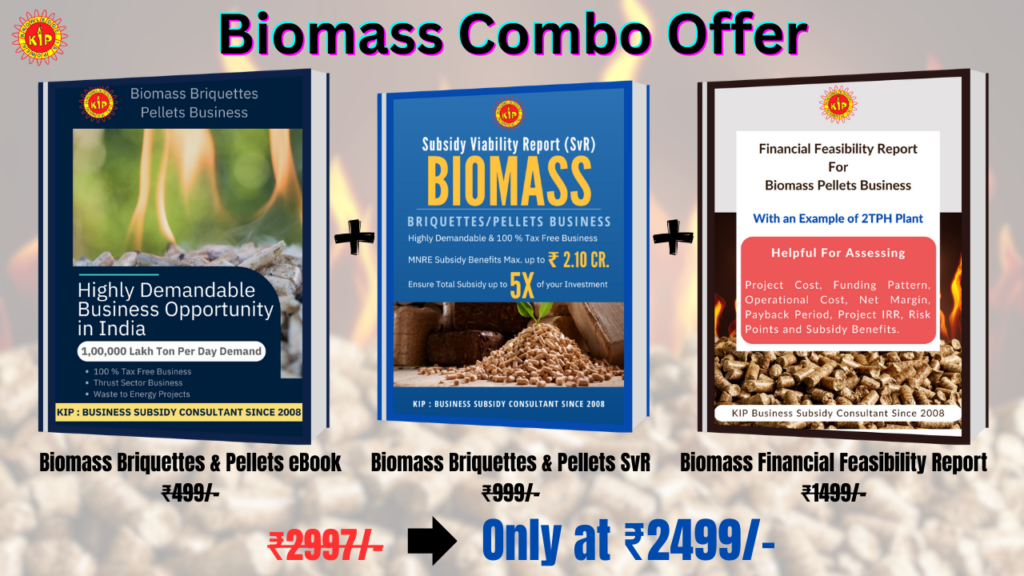

Or you can Download Biomass Specific Business & Subsidy Book : https://kipfinancial.com/biomass-sector-e-books/

Thanks & Regards

मला बायोमास पॅलेट कंपनी सुरू करायची आहे मार्गदर्शन करावे ही विनंती

Welcome in KIP

Great thanks for showing interest.

Further, you’re requested to kindly share your contact number so that we can contact to you for your requirements.

You may also connect with us on 8683898080.